York YK Chiller Motor Repair

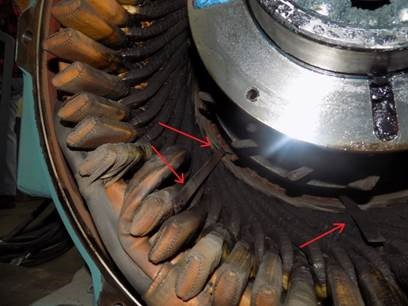

York YK Chiller Motor’s Stator with loose fiber wedges. Rubbing on rotor caused by loose fiber wedges. Bearing fluting caused by improper motor shaft grounding. Both issues were found through use of vibration analysis, which is an essential tool in predicting wear in chiller compressors and motors. We recommend taking vibration samples on chillers at […]